Importance of Employee Feedback

21 November, 2022

Patron Career Staffing firmly believes in adopting a tailored approach to meet temporary and permanent recruitment needs. We safeguard the interest of our clients by finding such workers who are knowledgeable and reliable.

About UsNeed help? Make a Call

32 Dundas Street East Unit A, L5A1W2

Can you imagine your life without food? It is more than simply a commodity that is sold or purchased from the market. It plays a massive role in our daily lives and drives economies worldwide.

The ultimate goal of all food manufacturers is that the food that is served on your table is uncontaminated and free from hazardous residues. The position has changed massively since the occurrence of the Covid- 19 pandemic. Ensuring the health and safety of end users of these industries is the topmost priority. To achieve this, food production companies are implementing necessary measures and best practices to lower the risk of food taint in manufactured commodities.

To serve this purpose, the management of the food production industry is preparing their workplaces to comply with food-safety norms. They are being completely aware of the health safety measures of the workers to safeguard consumer’s health also.

This article will discuss the best health and hygiene practices applied by food industry manufacturers in the post-COVID world.

Food manufacturers can play a vital role in preventing outbreaks and contamination from their products by simply following the health, hygiene, and safety practices that are enumerated below. For an industry like food manufacturing, the relevant market size is quite large, there are an endless number of consumers and therefore the need to keep everyone safe arises simultaneously. They ought to endure hefty responsibilities of not only levying tutelage for their staff and food handlers but also for their customers.

Food handlers can range from anybody who comes in contact with food either directly or indirectly during the manufacturing process. It is important to communicate your hygiene protocols to ensure compliance. Without proper coordination between management and workers and periodic training modules, it can lead to serious health risks among the masses. The protocol for adhering to safe food handling practices must be understood and followed by all such workers. There is no such thing as ‘too careful. Manufacturing hygiene will help prevent and reduce the likelihood of food-borne diseases, introduction, spread, and propagation of potential pathogens in production plants and industries.

Checklist for personal hygiene of food production handlers-

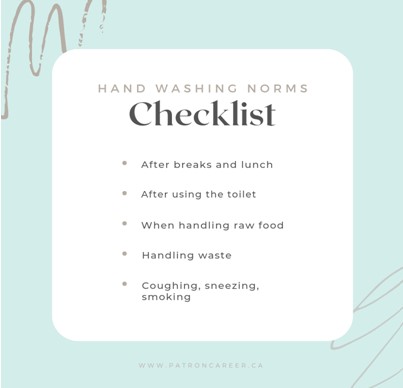

1. Hand washing

First and foremost, thing to mandate is effective hand washing techniques to ensure a safe work environment in food production plants.

The 1-minute thumb rule works wonders. Lather and scrub for a minute before entering the premises of production and when handling food production machinery.

Pro-tip: make workers use a warm waiter at 100 degrees Fahrenheit to remove dirt and contaminants from their hands. You should provide liquid soaps instead of bar soaps because the latter renders the formation of harmful bacteria.

2. Protective uniforms and equipment

Food production personnel have to handle and use tons of various tools, machinery, or equipment to cater to the production requirements. Make sure to provide them with necessary cleaning supplies and Personal Protective Equipment (PPE). The production, storage, transport, and equipment should be disinfected daily before the workers arrive. It is a good idea to supply apt resources such as production tools on your own.

Sanitize the workplace as much as you can. Essentially, provide coats/smocks, aprons, hairnets, gloves, shoe covers, masks, and shields. Otherwise, you can advise workers to keep separate clean uniforms for indoor activities in the plant and thereby avoid potential germs from the outside. Give your employees detailed Standard Operating Procedures (SOPs) to maintain the safety protocol of the workplace.

3. Infected workers

Do not let sick workers enter the production plants or handle produce at any cost. Give them a day or two to take rest and stay home, before allowing them to join work again. This is a mandate guideline because unwell workers would only raise the probability of cross-contamination and invite a bundle of problems for your workplace.

If any of your workers are suffering from the following symptoms, send them home immediately to avoid transmission of diseases, such as-

Checklist for operational hygiene of the food production industry-

1. Waste management

Manufacturing facilities must have in-built facilities for storage or disposal of waste such as sewage, one-time use protective ears, chemical effluents, etc. Establish adequate procedures because incorrect waste management will spread infestations and can lead to illness proliferation.

2. Pest control

Management must ensure proper food handling and preparation by eliminating any infestations of cockroaches, flies, and rodents. There is an air of pressure in the era of cove-19 because eventually safety in the workplace should be implemented with strict conditions. Keep all pest control measures in check to shun the spread of food-borne diseases. Also, monitor and detect these measures to save the potential health of your people and the consumers.

3. Staff training

Investing in training is critical for companies because only then employees will be properly educated on personal health and hygiene practices to facilitate a disease-free environment. You can adjudicate training by placing posters, signage, and demonstrations or personally coach employees to reinforce personal hygiene practices. Devote time and energy to explicating training operations so that your employees including supervisors, have a full-fledged understanding of the importance of basic sanitation and hygiene principles.

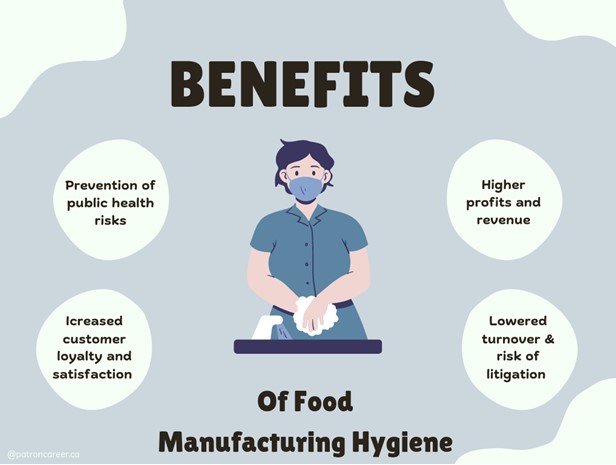

Maintaining the health and hygiene of food production workers is a mandatory standard that all companies in food manufacturing and processing line must follow. Adhering to the abovementioned practices will prevent the outbreak of food-borne decease such as E. coli and Salmonella. Identify and control potential food safety perils by conducting regular food safety audits to monitor the processes. This will lead to increased customer loyalty and goodwill.